As our castaway flag testifies, natural dyes offer a fairly limited range of colours. Until the discovery of synthetic alternatives, most natural dyes were derived from plants, and, to a much smaller extent, from shellfish or insects (if you're interested, visit 'Experiments with Natural Dyes').

As our castaway flag testifies, natural dyes offer a fairly limited range of colours. Until the discovery of synthetic alternatives, most natural dyes were derived from plants, and, to a much smaller extent, from shellfish or insects (if you're interested, visit 'Experiments with Natural Dyes').

They were only present in small amounts and their extraction was often inefficient, so they were usually expensive. The burgeoning textile industry of the 19th century created a need to manufacture larger quantities of cheaper and more versatile alternatives. The resulting synthetic dye industry became the 'high-tech' industry of Victorian times, and its acknowledged founder was an English chemist, William Henry Perkin.

In 1856, 18-year-old Perkin was experimenting in his home laboratory, trying to synthesise the anti-malarial drug quinine (found nowadays in tonic water). In an experiment with a compound called aniline, one of the simplest chemical components of coal tar,* he obtained a black precipitate. On testing its solubility, he serendipitously discovered that alcohol extracted a purple colour, which readily dyed silk, and was much more stable in sunlight than any other (natural) purple dye then in use. Amazingly, some of Perkin’s original dyed samples still exist and remain purple to this day.

* The dyestuffs industry was largely based on chemicals obtained from coal tar, a black, viscous by-product of gas production from coal. Initially regarded as a useless and filthy nuisance, coal tar turned out to offer an unimaginably rich treasure trove of chemicals. It’s astonishing that until about 30 years ago, nearly all synthetic dyes were ultimately derived from coal tar (and not only dyes, but chemicals like carbolic acid, TNT and saccharin).

He patented this first synthetic dye in August 1856, and set about manufacturing it on an industrial scale. Perkin had to develop large-scale production methods for his starting materials, and to do this he built a factory at Greenford Green in Middlesex. At first he called the dye aniline purple, but, following its success in France, it was renamed mauve (or mauveine), after the French word for the purple mallow flower.

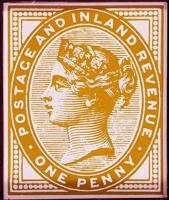

A technique was developed to apply the dye to cotton fabrics and soon everyone was using it. It was a sensation. French Empress Eugénie wore a dress dyed with mauve, and it became one of Queen Victoria’s favourite colours. From 1881–1901, even British ‘penny lilac’ postage stamps were coloured mauve.

A technique was developed to apply the dye to cotton fabrics and soon everyone was using it. It was a sensation. French Empress Eugénie wore a dress dyed with mauve, and it became one of Queen Victoria’s favourite colours. From 1881–1901, even British ‘penny lilac’ postage stamps were coloured mauve.

‘penny lilac’

In 1874, Perkin sold his business and retired to enjoy private research and family life. Fifty years after his discovery of mauve, he was knighted for his contribution to the British chemical industry. His achievement was not just the discovery of the dye but its development and exploitation.

Perkin showed that:

- Chemical research can give rise to useful and valuable materials.

- It’s possible to produce specialised chemicals on a large scale in processes that require several reactions to be carried out in succession.

- Co-operation between manufacturers and users is necessary for progress, and with the right product, chemical manufacture could be commercially viable.

The Industry

Despite Perkin’s success, the next 50 years of the British synthetic dyestuffs industry were disappointing. Chemists and industrialists everywhere (except Britain it seemed) were quick to see the possibilities opened up by Perkin.

The discovery of mauve sparked an international race to produce other synthetic dyes from the myriad chemicals in coal tar. Research was directed towards determining the structures of natural dyes that could then be synthesised in the laboratory, and subsequently manufactured on an industrial scale.

Alizarin and Indigo

Like many ‘natural’ dyes, alizarin and indigo are simple molecules, but until 1868 their chemical structures were completely unknown. In that year, alizarin was shown chemically to be derived from the hydrocarbon anthracene, obtained, of course, from coal tar.

Although the structure of anthracene itself was not known at the time, a starting material for the laboratory synthesis of alizarin was now available. In June 1869, Perkin and the German dye company, BASF, filed patents for the same synthetic route to alizarin just one day apart.

As a result, the industry producing the natural dye was killed off almost overnight. Perkin’s company alone was producing over 400 tonnes of synthetic alizarin a year and at less than half the price of the natural product. The demise of naturally derived indigo was equally dramatic. The German chemist Baeyer synthesised indigo in 1880, but it took more than 17 years and £2 million of research at BASF to produce a commercially viable industrial route. A few years later, the Indian indigo trade was dead. Almost all the indigo used from then until now has been synthetically derived. Only for a short time during the First World War was trade in the natural dye revived, but it succumbed almost immediately in the post-war period.

Dyes and the Pharmaceutical Industry

And it wasn’t just dyes. In his search for antiseptic substances that could be used to treat bacterial infections, a German physician, Paul Ehrlich, discovered that one of the dyes he used for staining his microscope slides actually killed bacteria. He found that the yellow dye flavine killed the germs responsible for abscesses.

This led to the development of a wide range of useful drugs, all derived from chemicals found in coal tar. In fact, today’s pharmaceutical industry can be regarded as having its roots in the dyestuffs industry.

German Industry Outstrips British

For half a century, Germany dominated the synthetic dyestuffs (and drugs) industry, with companies like AGFA, BASF, Bayer and Hoechst. Ironically, several of the chemists employed by these companies had learned their trade with British dye manufacturers before returning to Germany.

The British government had chosen to neglect the infant dye industry, and instead concentrated its support on the well-established textile industry. British patent laws, taxes and an inadequate educational system have all been cited as reasons for Germany’s chemical industry outstripping that of Britain.

By 1913, Germany was exporting about 135 000 tonnes of dyes compared to Britain’s 5 000 tonnes. At the outbreak of the First World War, the only khaki dye available for British army uniforms was manufactured in Germany and had to be imported secretly!

Imperial Chemical Industries

In 1926, the British government was forced to revitalise its chemical industry by bringing together several companies (manufacturing dyes, explosives, fertilisers, fibres, nonferrous metals, and paints) under the name Imperial Chemical Industries (ICI). Colour chemists set about developing new synthetic dyestuffs for use on the growing range of new synthetic fibres, like Nylon and Terylene, that were being developed at the time and couldn’t be dyed using traditional methods.

Today, the world’s dyestuffs industry produces around 500 000 tonnes of synthetic dye each year. It’s come a long way since the discovery of mauve.

WEBSITES

Society of Dyers and Colourists

Dye History from 2600 BC to the 20th Century

An Historical Overview of Dyes, Dyeing and Fabric Colors in the Renaissance

READING

Book 4 of ST240, Our Chemical Environment, The Open University, 1995 ISBN 0 7492 5144 1.

Chant C. (ed.), Science, Technology and Everyday Life (1870–1950), Routledge/Open University, 1991 ISBN 0 4150 3557 0.

Singer C. et al. (eds.), ‘Dyestuffs in the 19th Century’, Chapter 12, A History of Technology, vol. V, p. 257, Oxford University Press, 1958.

FURTHER GENERAL READING

Here are some books and articles that you may want to try and get hold of:

Barrow J. D., The Artful Universe, Oxford University Press, 1995 ISBN 0 1985 3996 7.

A quite remarkable book that will change the way you view the world. Extremely accessible.

Burton et al., Chemical Storylines, G. Heinemann Educational Publishers, 1994 ISBN 0 435 63106 3.

Part of the Salters Advanced Chemistry course, which explores the frontiers of research and the applications of contemporary chemistry. For A level and other science courses aimed at 16 to 19-year olds.

Fraser A. and Gilchrist I., Starting Science (Book 1), Oxford University Press, 1998 ISBN 0 19 914235 1.

Part of an integrated science course for the National Curriculum Key Stage 3 and Scottish Environmental Studies (science) for S1 and S2.

Northedge A. et al., The Sciences Good Study Guide, The Open University, 1997 ISBN 0 7492 3411 3.

Indispensable for students of science, technology, mathematics and engineering. Packed with practical exercises and activities, all aimed at making studying more enjoyable and rewarding. Lots of hints and tips for those returning to study.

Selinger B., Chemistry in the Marketplace, 5th edn., Harcourt Brace, 1998 ISBN 0 7295 3300 X.

An excellent and informative reference source for all kinds of real-life applications of chemistry. Explores the world of chemistry that surrounds us in our daily lives, explained in terms that everyone can understand. ‘Makes chemistry come alive.’

PS547 Chemistry for Science Teachers course materials, The Open University, 1992

A course designed for use by science teachers from a wide variety of backgrounds, with varying experience of teaching science. A familiarity with some basic science (perhaps physics or biology) is assumed, but little understanding of chemistry is required. The mathematical understanding needed for the course is not great.

Rate and Review

Rate this article

Review this article

Log into OpenLearn to leave reviews and join in the conversation.

Article reviews